One tab at a time...

This is where I

gave up last time I tried to make this thing.

I think it was

all those ^#($#@! little individual teeth on pieces 33 and 36.

I mean really now, you get piece 33 cut out, maybe you even

get the bracing pieces 34 (with all those ridiculous little

zigzags) and 35 (with the tiny little edges to fold over) cut

out. But then you still have piece 36. And THEN you have

to the glue individual slices of piece 37, each and every one.

Tip for pieces 34 and 37:

Before cutting out all the zigzags on piece 34 and all the

slices of piece 37, do your scoring with the tip of the Xacto.

After the pieces are cut out, it will be hard to make those

scores evenly.

Tip for

piece 33: The instructions don't say explicitly,

although a marker for a bead is indicated in the middle of

piece 33. This bead's purpose appears to be to make

putting the axle through the center of the wheel easier. Glue

it into place before you glue down piece 36.

Tip for piece 37: Cut

carefully make the strips out of piece 37. There are no

extras given, so if you make a mistake on one of the strips,

you'll have to improvise replacements.

There is a bead marker on piece

33 and do glue in a bead that will fit the large size axle.

It will help later when you're trying to thread the axle

through all the pieces. I don't have any good tips on making

piece 33 line up with piece 36 so that the tabs are also all

lined up. You just have to give it your best shot and try not

to get too frustrated.

Do take a break and congratulate

yourself once you've gotten the motor wheel assembled, or

you'll wind up with a neck cramp from "The Hunch" position.

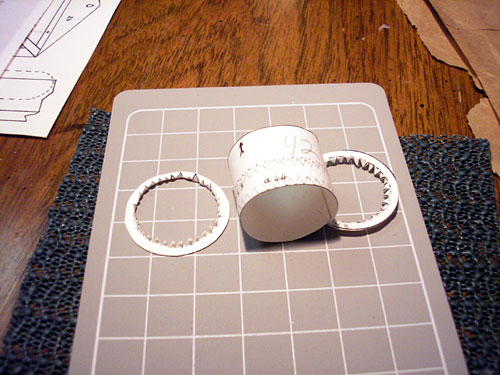

Below is a picture of our

assembled wheel, which only had one sorta questionably

attached tooth! (For extra points, spot the tooth.)

The pulley will be

attached to the motor wheel and that's pieces 39-49. Work in

numerical order and follow the cut instructions carefully.

Tip

for piece 39: Mark the "b" and the "c" on the

INSIDE of the piece before you cut those letters away.

Also note that the center lines of the triangle points need to

be cut, not scored. Tip

for piece 39: Mark the "b" and the "c" on the

INSIDE of the piece before you cut those letters away.

Also note that the center lines of the triangle points need to

be cut, not scored.

Glue piece 39 to 38 on the

star-shaped pattern.

Then glue the ends of piece 40

together.

Line up the "a" and "b" on piece 41 with the same letters on

piece 40 and then glue the marked end of 41 onto 40.

Put glue on the inside of piece

40, and then slip it over piece 39 -- making sure that the

arrow on piece 40 is pointing toward where the motor wheel

will be.

Put

together piece 42. Put

together piece 42.

Tip for

pieces 43 and 44: Before cutting out the pieces,

score the dashed lines first. This will make bending the

zigzags easier later. They are going to form the "collars"

that go over piece 42, the "throat" of the pulley.

Glue

piece 45 inside the "throat." It covers the zigzags of pieces

43 and 44. Glue

piece 45 inside the "throat." It covers the zigzags of pieces

43 and 44.

Now, wrap the free end of piece

41 around the pulley, and slip the barrel of piece 42 over it,

making sure that the arrow on 42 points toward the motor

wheel. Piece 42 will now turn freely in one direction,

but lock in the other. Now, wrap the free end of piece

41 around the pulley, and slip the barrel of piece 42 over it,

making sure that the arrow on 42 points toward the motor

wheel. Piece 42 will now turn freely in one direction,

but lock in the other.

Now glue pieces 46 and 47

together back to back, and then glue them to the open end of

piece 39 (the star-shaped pinion). Be careful not to let

them glue onto piece 42.

Note that piece 48 is mounted on

thick cardboard. It will need to be thick enough for a thin

rubber band to go around it. Make your axle holes as cleanly

as possible in this piece too -- it will be hard to push

through the cardboard.

Glue this piece onto the pulley

wheel and glue on the faceplate, piece 49. Assemble the

motor wheel by gluing the pulley onto the face of the motor

wheel, i.e. piece 38 onto piece 36.

This is the order they'll be in

when glued together:

Whew!

How about you stop and get a drink!

<== Back to

the FRAME

on to the MIDDLE WHEEL ==> |